Complete Tank Solutions Fabrication to Installation

Our comprehensive approach to diesel storage tank projects encompasses the entire project lifecycle from initial fabrication through final installation and commissioning. This integrated service delivery model ensures seamless project execution and optimal performance outcomes

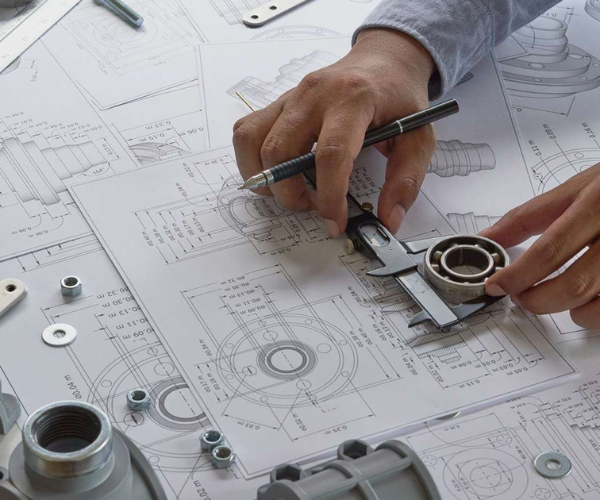

Fabrication Excellence

Installation & Commissioning

-

1Site Survey & PlanningLogistics, access, lifting study and schedule optimization to reduce execution risk.

-

2Foundation PreparationGeotechnical interface, load distribution and precision levelling to ensure structural integrity.

-

3Tank InstallationSafe lifting, alignment and mechanical connections executed by certified crews with QA oversight.

-

4Integration & HandoverSystem integration, functional testing, commissioning reports and client handover with O&M documentation.

Specialized Frac Tank & Modular Solutions

Frac Tank Fabrication

Custom-Engineered Frac Tanks

Built for high-pressure hydraulic fracturing with robust materials and construction to endure the harshest conditions.

Pipe Spool Manufacturing

Precision-Engineered Pipe Spools

Designed for optimal flow and compatibility, rigorously tested to guarantee reliable field performance.

Modular Structures

Industrial Support Structures

Quick to assemble, adaptable, and engineered to meet evolving process and operational requirements.

Technical Specifications

The frac tank project required specialized expertise in pressure vessel design, materials engineering, and field application considerations. Each tank was engineered to withstand high-pressure hydraulic fluids, temperature variations, and the demanding operational environment of hydraulic fracturing operations

Project Success: Delivered 3 frac tanks plus extensive pipe spools and modular structures for critical energy sector applications

Comprehensive Pipe & Structure Fabrication

Design Engineering

Advanced 3D modeling and stress analysis ensure optimal performance and seamless field integration for every fabricated component.

Precision Manufacturing

State-of-the-art fabrication equipment and certified welding procedures guarantee dimensional accuracy and structural integrity

Quality Validation

Comprehensive testing and inspection protocols ensure every component meets or exceeds industry standards and client specifications.

Manufacturing Capabilities

Our pipe spool fabrication encompasses carbon steel, stainless steel, and exotic alloy materials, utilizing advanced welding techniques including orbital welding for critical applications. Each spool is manufactured to precise dimensional tolerances with comprehensive fit up verification.

Modular structure fabrication integrates structural steel components with precision connection details, enabling rapid field assembly while maintaining long-term structural performance under demanding operational conditions.

Quality Assurance

Every fabricated component undergoes rigorous inspection protocols including dimensional verification, non-destructive testing, and pressure testing where applicable. Our quality management system ensures complete traceability from raw materials through final delivery.

Field installation support and technical consultation services

complement our fabrication capabilities, ensuring seamless project execution and optimal operational performance

Excellence in Execution: Custom pipe spools and modular structures manufactured to the highest standards for seamless field integration

Fabrication of Sea Water Filter for SABIC– 16 No’s